Here you can find out more about Fraunhofer IFAM's projects with sustainable aspects.

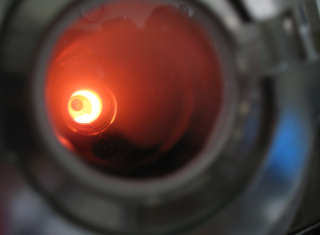

Up to 30 percent of energy can be saved if heating processes in industrial furnaces are controlled with pinpoint accuracy. Here, monitoring the process gases is a key to the energy turnaround in manufacturing technology.

more info