Up to 30 percent of energy can be saved if heating processes in industrial furnaces are controlled with pinpoint accuracy. Here, monitoring the process gases is a key to the energy turnaround in manufacturing technology.

»KonAIR«: A concept for energy-efficient debinding processes

Near-net-shape manufacturing processes such as metal powder injection molding or binder-based printing processes use organic binders that have to be removed later. The thermal removal of these auxiliary materials is very energy-intensive in production and is largely based on empirical values. Such processes are static and usually over-designed. In the BMWi-funded project "KonAIR" (concentration-dependent industrial furnace control), a concept was developed to gain precise control over such debinding processes.

Reduction of energy consumption through accurate material and process knowledge

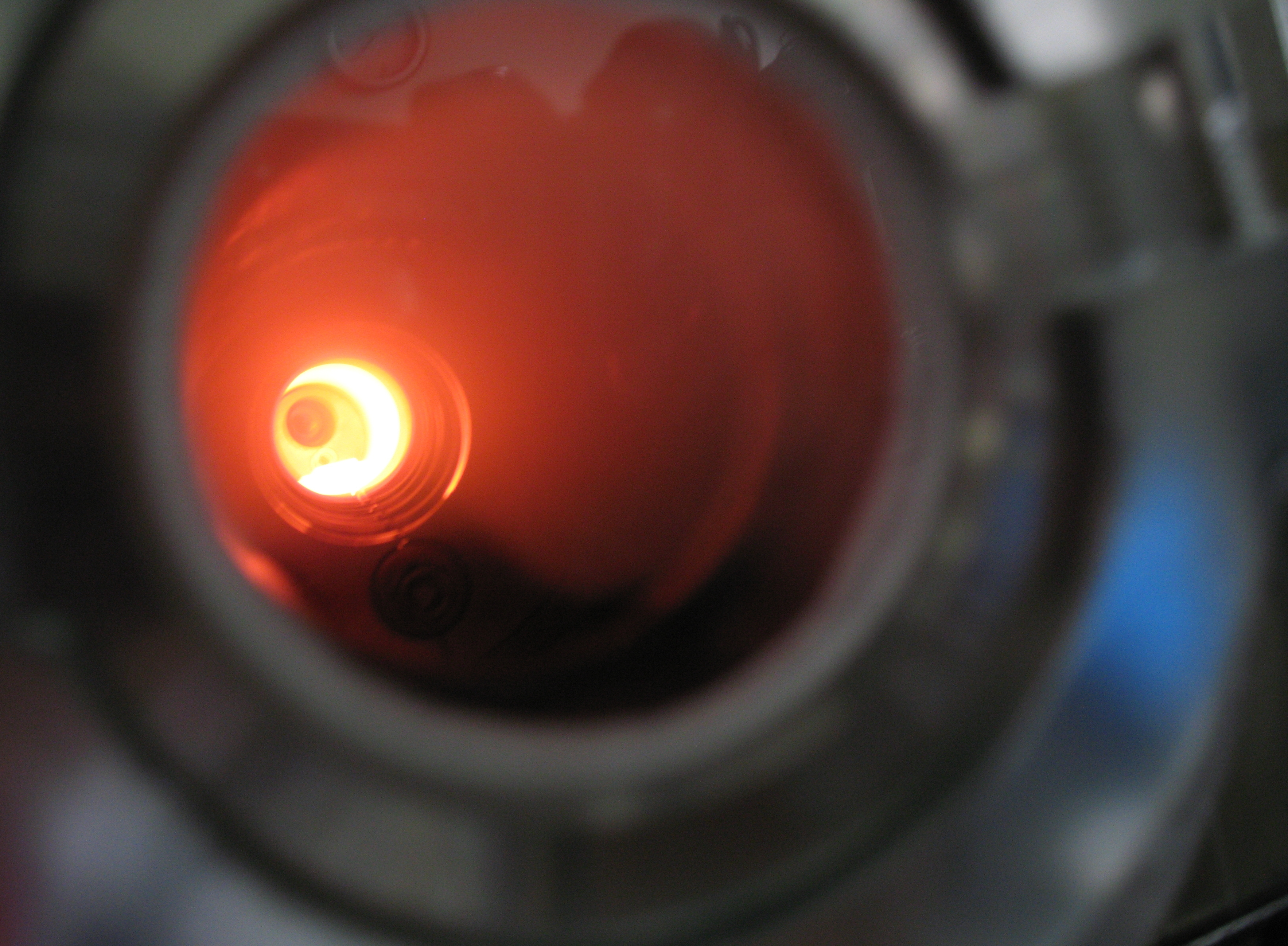

The key to this is the measurement of the process atmosphere in the furnace. At Fraunhofer IFAM in Dresden, it has been shown that the states of the sintered material in the furnace clearly correlate with the gas composition. With this knowledge, the correct process temperature and duration can be controlled in real time to the level actually required. The result of these efforts is a 25 to 30 percent reduction in energy consumption compared to the conventional process. In addition, scrap can be significantly reduced and component quality increased. This result was initially achieved in laboratory plants and has now been repeated in industrial production facilities.

Further applications besides powder metallurgy

Particularly for resource-efficient printing processes, such an improvement in energy efficiency is important to increase acceptance in the industry. In addition to powder metallurgy, such process gas-controlled industrial furnaces are also transferable to a whole range of other industries. For example, ceramic processes, the production of carbon-based materials or even the gasification of biomass can also be significantly optimized.